Toyoshima’s traceable wool journey with FibreTrace®

In response to market demand for traceable wool, large Japanese trading house Toyoshima has successfully trialled FibreTrace® technology to show the journey that wool takes along all stages of the supply chain from the fibre to the end product.

Consumers worldwide are increasingly interested in the source of their clothing. Consequently, for many brands, being able to demonstrate traceability along their supply chains is becoming an essential part of business.

Toyoshima is a large Japanese trading house handling various textile products including wool, with annual sales worth more than A$2.4 billion in 2023. In response to requests from its customers for traceable wool, Toyoshima has been looking for a traceability solution.

The amount of raw materials and yarn that Toyoshima handles is amongst the highest in Japan. The trading house handles both worsted and woollen yarns, and handles the largest amount of worsted yarn in Japan. It supplies yarn to Japanese weavers and knitters, but also trades in other wool products including woven fabrics which it sells to luxury brands in Europe.

Successful trial of FibreTrace technology

In its search for a traceability solution, Toyoshima has trialled FibreTrace® Fibre textile verification technology.

The technology involves FibreTrace’s non-toxic pigment ID being embedded within fibres to create a unique, scannable identifier that stays with the fibre throughout its entire journey and life, even if the fibre is reused or recycled. Using specialised scanning technology, the pigment can be detected and verified at any point in the supply chain, providing immediate, reliable confirmation of fibre authenticity and origin.

Toyoshima first became aware of FibreTrace technology during a visit to a textile factory in Vietnam, as part of a Woolmark-organised tour of Vietnamese suppliers in 2023. Toyoshima’s head of digital traceability Mr Okamoto contacted FibreTrace and subsequently decided to investigate the technology for Toyoshima’s wool business.

With support from Woolmark, Toyoshima earlier this year successfully trialled the FibreTrace technology along one of its wool supply chains tracing the production of three jumpers from the fibre in Australia to the end products. As a result of the successful trial, Toyoshima feels there is a huge business potential in FibreTrace technology for the larger-scale traceability of wool through the supply chain.

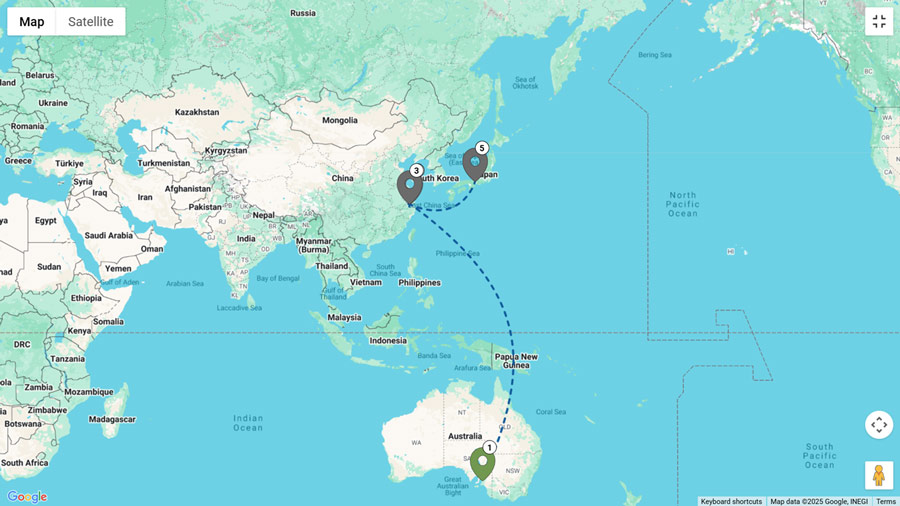

Scanning the QR code on the jumper’s swing tag opens a map that shows the journey along all the stages of the supply chain from fibre to end product. In this case it showed (1) the wool scourer in Australia, (2) top maker in China, (3) spinner in China, (4) knitter in Japan, (5) the jumper at Toyoshima’s head office exhibition. Pictured in the top image at the exhibition are AWI Product, Education Extension & Trade Licensing Manager, Japan, Tomohiro Nishizawa; Toyoshima’s Mr Takeshi Okamoto holding the jumper and swing tag; AWI Regional Manager Japan & Korea, Samuel Cockedey, holding a FibreTrace scanner; and Toyoshima’s Mr Junya Nakai.

Scanning the QR code on the jumper’s swing tag opens a map that shows the journey along all the stages of the supply chain from fibre to end product. In this case it showed (1) the wool scourer in Australia, (2) top maker in China, (3) spinner in China, (4) knitter in Japan, (5) the jumper at Toyoshima’s head office exhibition. Pictured in the top image at the exhibition are AWI Product, Education Extension & Trade Licensing Manager, Japan, Tomohiro Nishizawa; Toyoshima’s Mr Takeshi Okamoto holding the jumper and swing tag; AWI Regional Manager Japan & Korea, Samuel Cockedey, holding a FibreTrace scanner; and Toyoshima’s Mr Junya Nakai.

“Toyoshima has an important obligation to ensure transparency in the supply chain for the products we provide to our customers. FibreTrace is a unique supply-chain solution that merges its proprietary physical technology with blockchain-based digital measures. We are pleased and excited to collaborate with AWI to deliver Australian wool to our Japanese customers with complete peace of mind,” Mr Okamoto said.

Traceability back to the farm

FibreTrace pigment is usually embedded in wool fibre during the wool scouring process. However, Toyoshima in the future wants to show traceability all the way back to the specific farm.

Toyoshima and Woolmark are investigating ways to digitally connect FibreTrace with the Australian Wool Traceability Hub (AWTH). The AWTH is an Australian wool industry-owned digital platform to track the journey of wool from farm to first-stage processor. If connected, FibreTrace and AWTH would provide an entire chain of custody from the farm to the end product, creating an even better provenance story at retail for the end product.

“Toyoshima is one example of many companies outside of Australia that are developing or working with digital traceability platforms. By getting as many bales of Australian wool as possible into the AWTH system will help promote Australian wool and build demand for the fibre,” said AWI Program Manager, Woolmark Certification & Traceability, Mark Scott.

FibreTrace Technologies Ltd, Asia Pacific Regional Manager Rebekah McQuoid, says FibreTrace is thrilled to be collaborating with Toyoshima and the Australian wool industry.

“We’ve seen outstanding global success in marking Australian Cotton, with more than 250,000 FibreTrace marked Good Earth Cotton bales sent globally in the past three years; delivering real-time, end-to-end transparency from farm to store and beyond. We're excited to bring that same level of traceability to Australian wool. Now, Australian wool can carry its story – with physical and digital traceability – wherever it goes, helping build the ultimate full-circle, sustainable economy,” Rebekah said.

More information:

www.toyoshima.co.jp

www.fibretrace.io

www.awth.com.au

This article appeared in the Winter 2025 edition of AWI’s Beyond the Bale magazine that was published in June 2025. Reproduction of the article is encouraged.