Good news on wool residues

Studies funded by AWI clearly show that the incidence of agricultural chemical residues in Australian greasy wool is very low. This is good news for the wool industry in its push to market the fibre’s positive eco credentials amongst environmental rating agencies, governments, the textile trade and consumers.

Studies funded by AWI clearly show that the incidence of agricultural chemical residues in Australian greasy wool is very low. This is good news for the wool industry in its push to market the fibre’s positive eco credentials amongst environmental rating agencies, governments, the textile trade and consumers.

With brands now attuned to consumer concerns about the environmental impact of products, a central part of AWI’s fibre advocacy strategy is to demonstrate wool's environmental stewardship.

Since 2001, AWI has sponsored an annual survey of a wide array of agricultural chemical residues in Australian greasy wool. These chemicals are used by woolgrowers to control external parasites (lice and blowflies).

AWI monitors residue levels to ensure wool is suitable for sale into markets that are interested in the provenance of their products, including chemical residues remaining on fibres.

THE ISSUE

Some environmental apparel ratings agencies have already used toxicity in their ratings of fibres (eg 40% of MADE-BY’s total environmental score was based on chemical toxicity), while other agencies (eg Sustainable Apparel Coalition) have flagged their intent to add toxicity to their environmental assessments. These ratings agencies are important in the industry because apparel brands use the agencies’ ratings to help decide which type of fibre to include in their products.

Furthermore, these agencies influence government policy and there is a real likelihood in the near future of regulatory requirement for environmental impact indicators at point of sale (such as on ‘swing tags’ on clothing) in the European Union (EU). Additionally, a ban on certain applications of neonicotinoids has already been imposed in the EU (eg in cropping sprays), but the ban might well evolve to apply to neonicotinoid residues (such as from pour-on lice and blowfly treatments).

THE GOOD NEWS

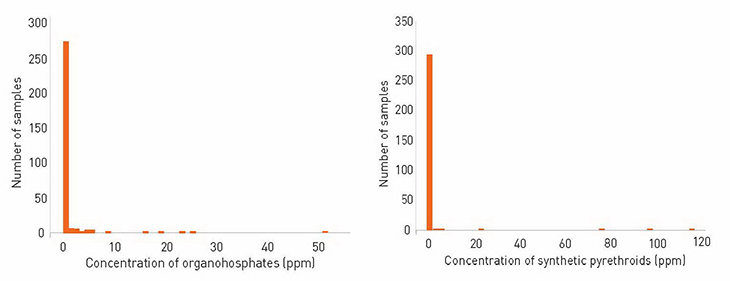

In light of these threats, the good news is that AWI has been undertaking studies that confirm favourably low and decreasing trends in residual pesticides remaining in Australian greasy wool. Tests have been carried for chemicals including Organophosphates (OPs), Organochlorines (OCs), Synthetic Pyrethroids (SPs) and specific Insect Growth Regulators (Diflubenzuron, Triflumuron and Dicyclanil).

Residues of the older chemical groups (OP and SP) have declined toward a mean (average) of near zero. In fact, the vast majority of sale lots do have actual zero or virtually zero residual pesticide – see Figure 1 below showing the distribution of samples grouped according to their OP and SP concentrations.

Figure 1: Organophosphate (OP) and Synthetic Pyrethroid (SP) distribution

“The studies funded by AWI demonstrate a proactive wool industry that is continually improving its environmental and safety performance,” said AWI Program Manager, Fibre Advocacy & Eco Credentials, Angus Ireland.

“This body of work will give confidence to environmental apparel ratings agencies and the broader textile industry regarding toxicity in wool; these favourable results reflect careful management practices by farmers servicing the apparel wool industry, increasing confidence all along the supply chain.”

AWI will be marketing its chemical residue monitoring data. The results have already been presented at the International Wool Textile Organisation (IWTO) Wool Round Table meeting in December.

Plans include publication in a peer-reviewed journal to target environmental apparel ratings agencies and the broader life cycle analysis (LCA) industry as well as communications and marketing for the wider textile industry, brands and consumers.

This article appeared in the March 2020 edition of AWI’s Beyond the Bale magazine. Reproduction of the article is encouraged, however prior permission must be obtained from the Editor.